Industry News

DarkSky International Updates Luminaire Certifications

DarkSky International has announced significant updates to its DarkSky Approved Luminaires program, a globally recognized certification initiative aimed at combating the escalating crisis of light pollution. Originally launched in 2002…

Two Presentations To Consider At LightFair 2025

It’s less than two weeks until LightFair in Las Vegas, NV. I’m looking forward to it, but not just for the trade show. I’ll also be part of two…

Fundamentals Of Energy Efficient Lighting And Controls

The Association of Energy Engineers (AEE) has announced the release of a new book, Fundamentals of Energy Efficient Lighting and Controls, now available through the AEE Bookstore. This comprehensive guide…

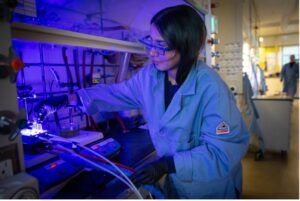

LED Lights & Photocatalysis Breakdown PFAS Forever Chemicals

Researchers at Ritsumeikan University in Japan as well as Colorado State University have developed a groundbreaking method that achieves complete breakdown of perfluoroalkyl substances (PFAS), commonly known as “forever chemicals,”…

Lighting Changes In LEED Version 5

In LEED v5, lighting environment is a key focus, with options for reducing glare and improving daylight access, and a new “Lighting Environment” credit. This credit allows projects to earn points…

High Performing Categories In Decorative Lighting

The magazine Designers Today asked lighting manufacturers at High Point Market what were some of their best-performing categories. The answers highlight key categories and product preferences driving demand in…

Z-Wave Evolving In The Smart Home

The role of Z-Wave in the smart home industry is evolving, particularly in light of the emergence of Matter, a new universal standard for smart home connectivity. Z-Wave, once…

Light Turned Into A Supersolid

Researchers have achieved a groundbreaking milestone by transforming laser light into a supersolid—a quantum state that exhibits both crystalline solid structure and frictionless fluid flow. Published in Nature, this work…

EV Charger Rebate Trends In 2025

Briteswitch recently covered key trends in electric vehicle (EV) charger rebate programs for 2025, emphasizing their growing importance in supporting EV infrastructure amidst a volatile market caused by federal…

US DOE Finalized GSL Test Procedure

The U.S. Department of Energy (DOE) has finalized and published clarifications to the test procedures for General Service Lamps (GSLs), including changes to how tunable white lamps are tested and expanded…