Craig DiLouie, LC, CLCP recently had the opportunity to interview Szymon Slupik, President, CTO, Silvair about Bluetooth SIG’s new full-stack wireless lighting control standard, Bluetooth NLC.

Craig DiLouie

LED Outdoor Lighting: Finding New Value

Today’s outdoor LED lighting offers a range of utility covering optics, color output, controllability, connectivity, and energy efficiency, writes tED Magazine lighting columnist Craig DiLouie, LC.

Craig’s Lighting Articles, Interviews + Opinion

Acuity’s Eric Gibson Talks Outdoor Lighting

I recently had the opportunity to interview Eric Gibson, Director, Product Market – Commercial Outdoor, Acuity Brands, for an article I developed for the November 2023 issue of tED Magazine, the official NAED publication. The topic: what’s new in outdoor lighting. DiLouie: According to the Department of Energy in its last SSL forecast in 2019, [...]

Codes + Standards, Craig’s Lighting Articles, Interviews + Opinion

DLC’s Andrew Antares Talks Light Pollution Mitigation

I recently had the opportunity to interview Andrew Antares, Project Manager of Technical Development, DesignLights Consortium (DLC), for an article I developed for the November 2023 issue of Electrical Contractor Magazine, the official NECA publication. The topic: new sample language that municipalities can use to address “light pollution” as a potential byproduct of outdoor lighting.

Craig’s Lighting Articles, Interviews + Opinion, Light + Health

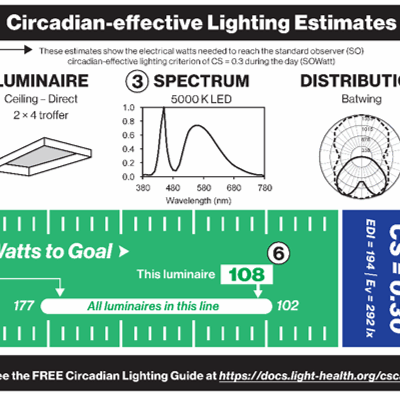

Interview: A New Method for Evaluating Circadian-Effective Lighting

For an upcoming article for Electrical Contractor Magazine, I recently had the opportunity to interview Mariana G. Figueiro, PhD, Director of the Light and Health Research Center (LHRC) and Professor in the Department of Population Health Science and Policy at the Icahn School of Medicine at Mount Sinai, and Professor Mark S. Rea. The topic: a new methodology (called SOWatt), which specifiers could use to evaluate the relative energy efficiency of luminaires in delivering circadian-effective light.

Signify’s Keith Eagle Talks Commercial Lighting Upgrade Opportunities

For an upcoming article for tED Magazine, I recently had the opportunity to interview Keith Eagle, Vice President & General Manager, US Professional Channel, Signify, on the topic of continuing opportunity with commercial lighting upgrades as the LED installed base grows. Transcript follows.

Cree’s Erik Milz Talks Commercial Lighting Upgrades

For an upcoming article for tED Magazine, I recently had the opportunity to interview Erik Milz, VP Product Strategy, Cree Lighting, on the topic of continuing opportunity with commercial lighting upgrades as the LED installed base grows. Transcript follows.

PNNL’s Gabe Arnold Talks Upper-Air GUV

For an upcoming article for ELECTRICAL CONTRACTOR, I recently had the opportunity to interview Gabe Arnold, PE, Senior Systems Engineer for Pacific Northwest National Laboratory (PNNL). The topic: a new ACEEE conference paper evaluating the efficacy and energy consumption of upper-room GUV systems. Transcript follows.

Craig’s Lighting Articles, Interviews + Opinion

Acuity’s Daren Hatfield Talks Field-Replaceable LED Drivers

I recently had the opportunity to interview Daren Hatfield, Director of Marketing – Digital Lighting Components, Acuity Brands for an article I’m developing for the May 2023 issue of tED Magazine, the official NAED publication. The topic: opportunities for distributors serving the LED driver replacement market.

Craig’s Lighting Articles, Interviews + Opinion

BriteSwitch’s Leendert Jan Enthoven Talks Lighting Rebate Trends

For a feature to be published in Electrical Contractor’s April issue, I recently had the opportunity to interview Leendert Jan Enthoven, President, BriteSwitch, a rebate fulfillment firm, whose North American rebate database provided a look at some interesting trends in commercial lighting rebates.