Chinese manufacturer, EXC Technology, claims to have surpassed the 250 lumens per watt (lm/W) efficiency barrier—a significant milestone in the pursuit of more energy-efficient outdoor lighting. The company, based in Shenzhen, unveiled its MYS4C/MLS6C module, reporting a luminous efficacy of 250.5 lm/W. EXC attributes this high efficiency to a combination of advanced optical design, [...]

LED + SSL

LED + SSL, Products + Technology

Nano-Engineered Eu3+-Based Phosphor Claims 10-20% Higher LPW

Seaborough B.V., a Netherlands-based leader in nano-engineered downconverters, and Luminus Devices have announced a partnership to bring the world’s first LEDs with nano-engineered Eu3+-based phosphor to market, on a commercial scale. This new partnership gives Luminus Devices early access to Seaborough’s unique phosphor technology, EuroLED, which Seaborough claims to be a high quality, more sustainable, [...]

LED + SSL, Products + Technology

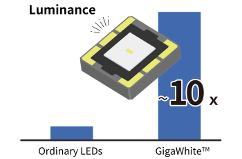

Nichia Releases GigaWhite White Laser SMD

Nichia has launched GigaWhite, an ultra-bright SMD white laser diode surface mount device (SMD) created by combining a blue laser diode (LD) and phosphor. It was developed for automotive headlights, specialty lighting, and industrial lighting. Nichia’s technology has achieved uniform light with less color irregularity. Taking advantage of the characteristics of its ultra-high luminance, [...]

LED + SSL, Products + Technology

An Additional Look At Liquid Cooling

I previously wrote about the potential of liquid cooling for high power LED luminaires, here. Liquid cooling is becoming increasingly popular for AI servers in advanced data centers, the charging cables for high-powered Level 3 EV chargers, and even next gen EV batteries. Traditional air-cooling methods can no longer meet thermal dissipation requirements for these [...]

LED + SSL, Products + Technology

Will Liquid Cooling Take Off In The Lighting Industry?

Liquid cooling is taking off as a critical thermal management technology for the booming AI data center industry. Liquid cooling protects AI servers from damaging heat, and also reduces energy consumption for cooling AI data centers. Can liquid cooling help with LED luminaire thermal management? In the early days of LED technology, LEDs were inefficient [...]

LED + SSL, Products + Technology

Micro-LED, Augmented Reality Contact Lenses

Mojo Vision, a California-based company, has been developing smart augmented reality (AR) contact lenses since 2015. In June 2022, they successfully demonstrated a functioning prototype of their “Mojo Lens,” marking a significant milestone in the development of AR contact lens technology. The Mojo Lens features an impressive array of miniaturized components: A Micro LED display [...]

LED + SSL, Products + Technology

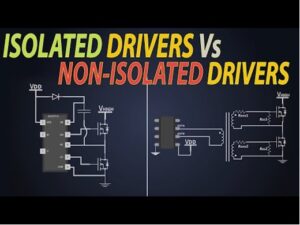

Increasing Use Of Non-Isolated LED Drivers And What To Know

In commercial and industrial LED lighting, drivers historically were isolated using transformers to step-down voltage, however there is increasing use of non-isolated drivers. Understanding Isolated Drivers An isolated driver is an electrical device that employs a transformer to step down high voltage to a lower one, which is then rectified into DC output. The term [...]

LED + SSL, Products + Technology

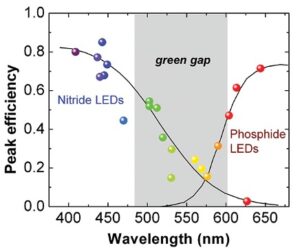

Closing The Green Gap To Unlock A Color-Mixed White Future

I’ve previously written about predictions for color-mixed white LED’s (CM-LEDs) to eventually surpass phosphor-converted LEDs (PC-LEDs) in both efficacy and spectral tuning capabilities. More on this is available here. But what is it going to take to bring about all of the advantages of CM-LEDs for general lighting? The primary technical barrier is the very [...]

LED + SSL, Products + Technology

OLEDWorks Announces New Automotive Brand, Atala

For a couple years, OLEDWorks has been developing and supplying cutting edge OLED tail lights to Audi. These tail lights go beyond indicating breaking. They also provide symbols alerting drivers behind the tail lights of accidents, construction, other road hazards, and personalization of the tail lights, by the owner. More information on the latest [...]

LED + SSL, Products + Technology

How Micro Lens Arrays (MLAs) Improve Visual Intelligence In Architectural Lighting

By: Kevin Green, Global Commercial Director, BrightView Technologies There is a fundamental demand uniting lighting objectives across outdoor and indoor architectural environments. Whether it’s spotlighting specific design features or illuminating a room with unique light patterns, precision is the name of the game in bringing innovative concepts to life. As architectural demands have grown more [...]